Area Under the Curve - The Importance of Capturing Gust Energy

info@upriseenergy.com

info@upriseenergy.com

The area under the wind curve is critical to understanding the importance of wind machines and their ability to capture a reasonable percent of that energy.

The shape of the curve is infinite, and subject to great scrutiny.

It is not difficult to make good power when the wind is strong and steady.

It is very difficult to make good power in low and moderate wind speeds where winds are variable and gusty.

Most of the world does not have strong and steady winds.

Most of the world’s population does not live in strong and steady winds. Many millions of these people are not connected to a power grid.

These are the millions who would benefit from the Uprise wind machine.

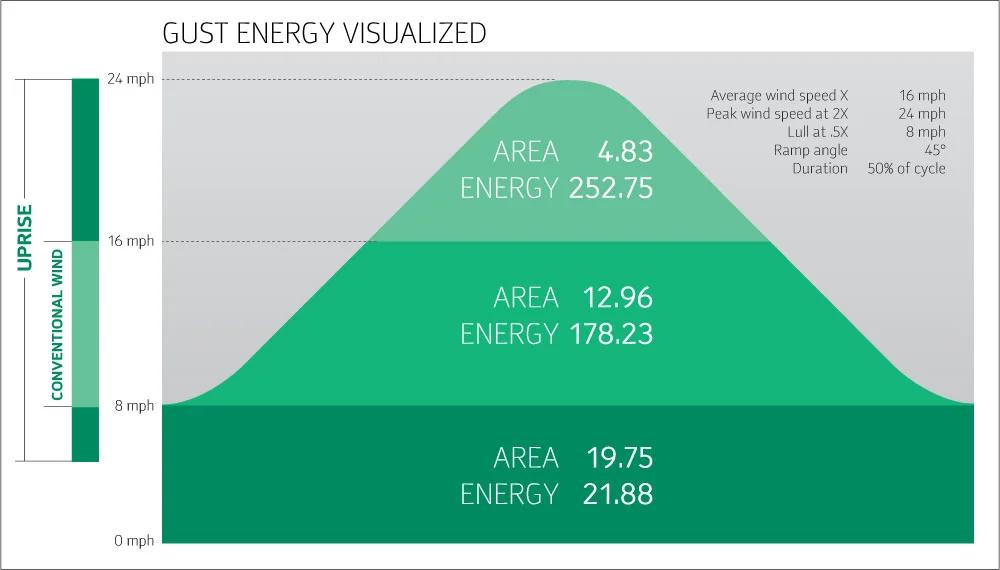

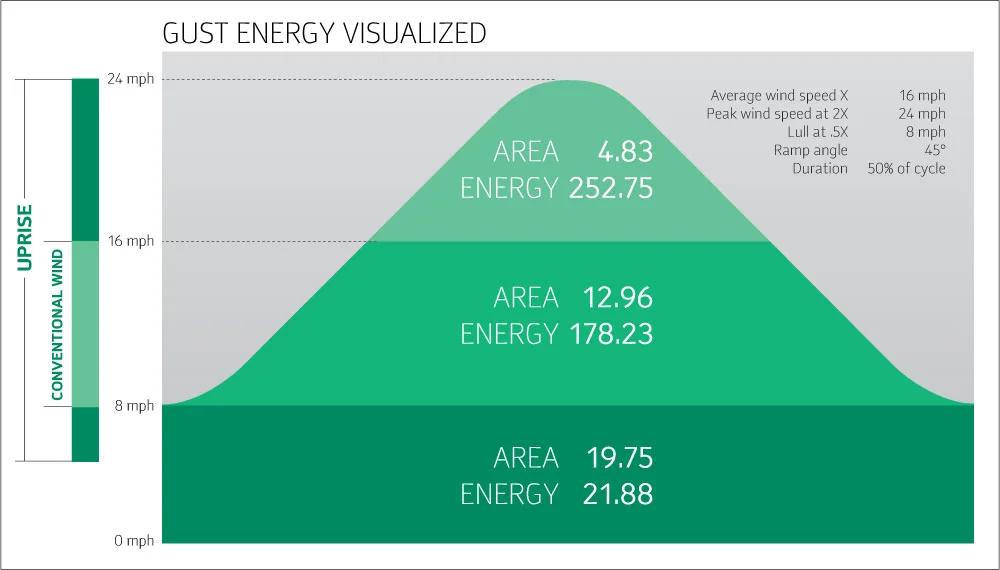

The shape of this wind curve has been chosen to reflect an average wind speed of 16 mph, with maximum and minimum wind speeds of double and half of the average speed.

The shape and values of the wind curve are infinite. Regardless, any wind curve shape results in approximately the same comparison.

Energy above average wind speeds is always greater than energy values below the average wind speed, by double or more.

This is significant. Especially if a wind machine does not, or cannot, effectively capture kinetic energy in wind gusts. This is exactly the constraint that conventional wind machines suffer.

This is exactly what the Uprise wind machine is designed for.

Conventional wind machines use a variety of methods to maintain constant RPM and prevent overload. The most common is pitch stall, which turns the blade into the wind to prevent an increase in RPM and/or prevent unacceptable power surges. The net effect is that a conventional wind machine does not seek nor capture the energy in wind gusts. Therefore the energy threshold in a conventional machine is limited to average wind speeds.

The Uprise wind machine does seek and capture the kinetic energy in wind gusts, which is shown to be more than double the energy in steady wind.

The principle design features in the Uprise wind machine that enable this is the “brains” of the machine that allow the rotor to maintain optimum tip-speed- ratios, the fluid transmission that allows the rotor and generator to spin at their optimum RPM, and the “match the load” characteristic of the synchronous generator. All of these must be coordinated in the computer programming.